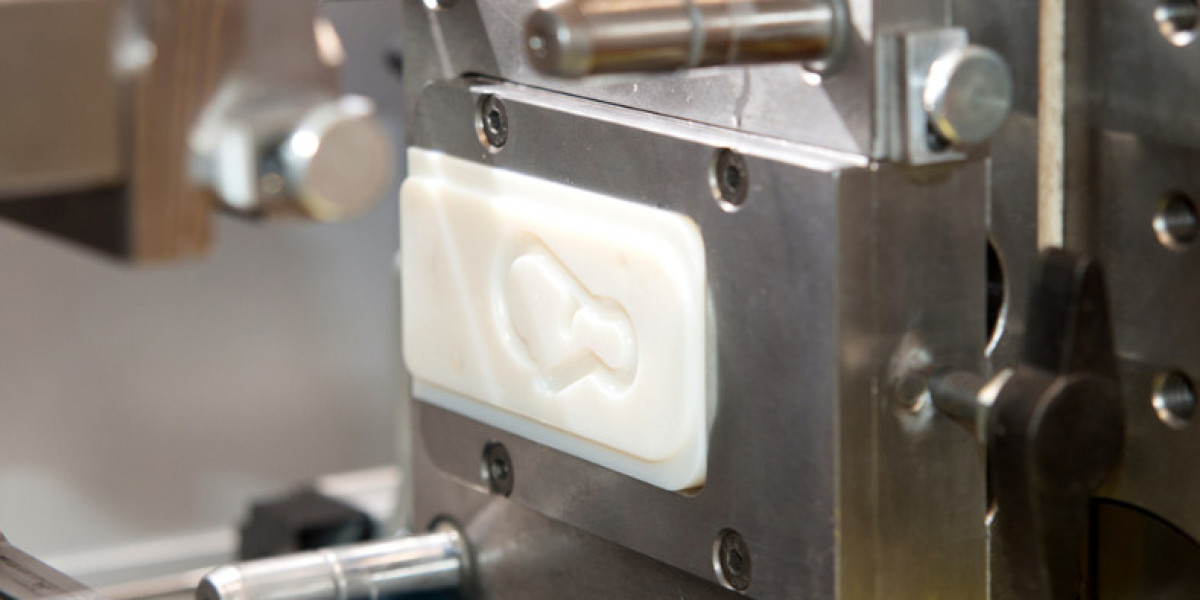

Flash occurs when molten plastic escapes from the mold cavity during injection, typically at the parting line. Proper mold clamping force and precision in mold design are essential to prevent flash and ensure clean, defect-free parts. Manufacturers must carefully select materials that balance cost with the necessary performance characteristics to ensure a cost-effective production process. Solution: Aside from reducing the thickness of the thickest wall sections, you may also need to lower mold temperatures, increase holding & prolong holding time in order to allow for sufficient cooling and curing.Jetting When it comes to material selection for medical device plastic injection molding, it’s important to work with a molding company that’s been entrusted by the medical manufacturing industry to identify the best resin for a given device and who specializes in engineered resins.

What Is A Puller Groove For Injection Molding

The significance of understanding the life cycle of molded products is crucial for sustainability efforts. Manufacturers are exploring eco-friendly options and recycling initiatives to reduce waste and promote responsible consumption. Cycle time optimization is crucial for maximizing production efficiency. Balancing injection pressure, cooling time, and mold temperature can significantly reduce production costs while maintaining consistent part quality across high-volume runs. PMC specializes in molding engineering-grade resins. If you are using a commodity molder but believe your application falls into the engineering-grade category, we can help. Contact us and we can help you select the right material for your part.Molding Gate Design We make device components that help our military defend themselves, and make it possible to return home to their families safely.

How To Run An Injection Molding Machine

Key advantages of injection molding include high production rates and consistency in quality. Automated systems can produce thousands of identical parts quickly, making it ideal for large-scale manufacturing in industries like automotive and consumer goods. If there is insufficient mold temperature the molecules will solidify prior to packing and at different rates, causing mold warpage. The injection molding cycle consists of several stages, including injection, cooling, and ejection. Each stage must be precisely timed to achieve the desired outcome. Proper management of these stages is vital to minimizing production costs and maximizing efficiency. Start a conversation with an expert at PMC today for assistance with your medical injection molding project. Contact Us  Electric injection molding machines are gaining popularity due to their energy efficiency and precision. Compared to hydraulic machines, electric models offer faster cycle times and reduced energy consumption, making them an attractive option for manufacturers.

Electric injection molding machines are gaining popularity due to their energy efficiency and precision. Compared to hydraulic machines, electric models offer faster cycle times and reduced energy consumption, making them an attractive option for manufacturers.