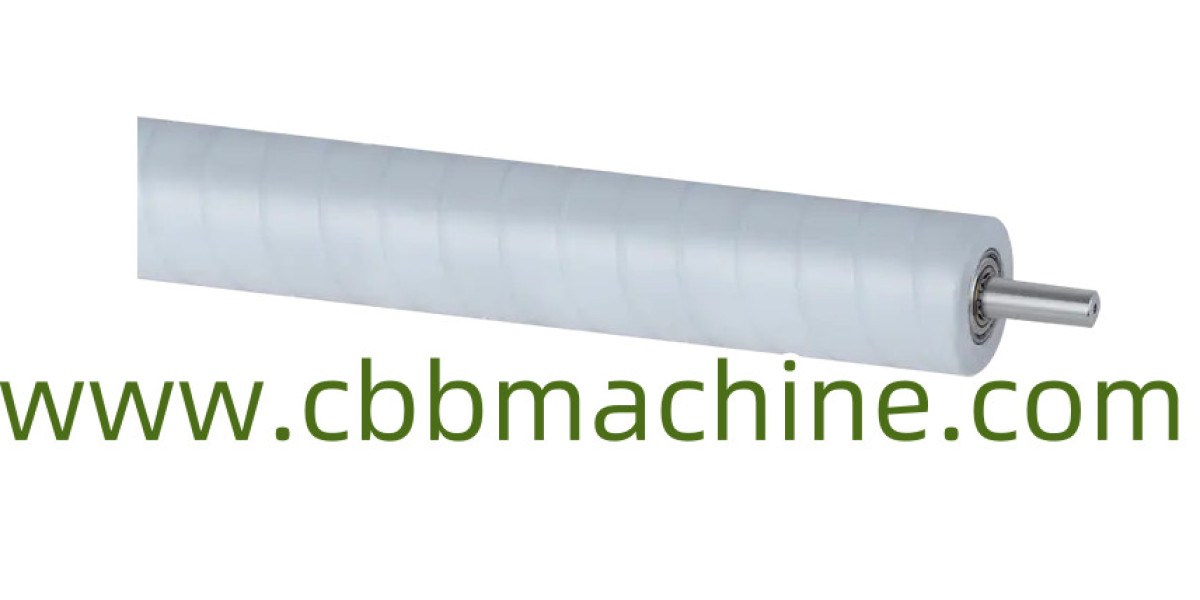

Enhancing Industrial Performance with Aluminum Rollers

In today’s fast-paced manufacturing environments, precision components are essential for reliable and efficient operations. Among these, the Aluminum Roller plays a key role across various industries including printing, textiles, film, packaging, and more. Its strength-to-weight ratio, resistance to corrosion, and adaptability make it a preferred choice for many material handling and processing systems.

What Is an Aluminum Roller?

An aluminum roller is a cylindrical mechanical component primarily made from aluminum alloy. It’s engineered to support, guide, or press moving materials in automated systems. Due to its lightweight construction, it reduces system load and increases energy efficiency, which is valuable in high-speed production environments. Aluminum rollers are customizable in terms of length, diameter, shaft design, and surface finish to match specific industrial applications.

Benefits of Using Aluminum Rollers in Industrial Systems

The advantages of aluminum rollers extend far beyond simple mechanical function. Here are some notable benefits:

Lightweight & High Strength: Aluminum provides structural strength while significantly reducing overall weight, allowing machines to operate at higher speeds with less wear.

Corrosion Resistance: Ideal for environments where moisture or chemicals are present, aluminum resists rust and oxidation, improving durability.

Custom Surface Finishing: Aluminum rollers can be anodized, knurled, coated, or polished depending on the required friction or material interaction.

Thermal Conductivity: Aluminum dissipates heat efficiently, which can be important in high-friction or heated processes.

Recyclability: As a sustainable material, aluminum is recyclable, aligning with eco-conscious manufacturing goals.

Applications Across Industries

Due to their versatility, aluminum rollers are applied in a wide range of industries:

Printing: Used in offset, flexo, and digital presses for consistent paper handling.

Textiles: Assist in the conveyance and treatment of fabrics during dyeing, coating, and drying.

Film and Foil: Ensure wrinkle-free transport and alignment of thin materials.

Packaging: Facilitate folding, sealing, and lamination processes with accuracy.

Converting & Laminating: Support precise tension and pressure in converting equipment.

Every industry that uses roll-to-roll technology can benefit from the inclusion of precision-engineered aluminum rollers.

Surface Treatments and Custom Options

To adapt to specific machinery and production needs, aluminum rollers come with various surface treatments:

Anodized Surface: Enhances wear and corrosion resistance.

Rubber Coating: Adds grip and cushioning for delicate materials.

Teflon Coating: Prevents sticking for adhesive-related applications.

Mirror Polish: Reduces friction and improves appearance for clean processing.

The choice of surface finish depends on the handled material and environmental conditions in which the roller operates.

Key Considerations When Selecting Aluminum Rollers

When choosing an aluminum roller, manufacturers should consider:

Load Requirements: Heavier materials may need a reinforced core or shaft.

Speed of Operation: Lightweight rollers help minimize inertia during fast processing.

Chemical Exposure: Environments involving solvents or moisture require enhanced corrosion protection.

Temperature Conditions: High temperatures may affect roller coatings or material properties.

These considerations help ensure compatibility between the aluminum roller and the machinery it supports.

Conclusion

The aluminum roller has become a crucial component for countless industries due to its strength, corrosion resistance, and customizable options. Whether it's guiding paper through a press or conveying film through a lamination process, aluminum rollers offer manufacturers a reliable and adaptable solution. Their contribution to improving system efficiency and reducing energy consumption makes them a strategic component in modern manufacturing setups.

To explore a wide range of high-performance aluminum rollers and related components, visit: